Dallas Fort Worth International Airport Asset Data Collection

Grapevine, Texas

Michael Baker performed asset data collection at the Dallas Fort Worth International Airport (DFW), the second largest U.S. airport by land mass and third busiest in the world.

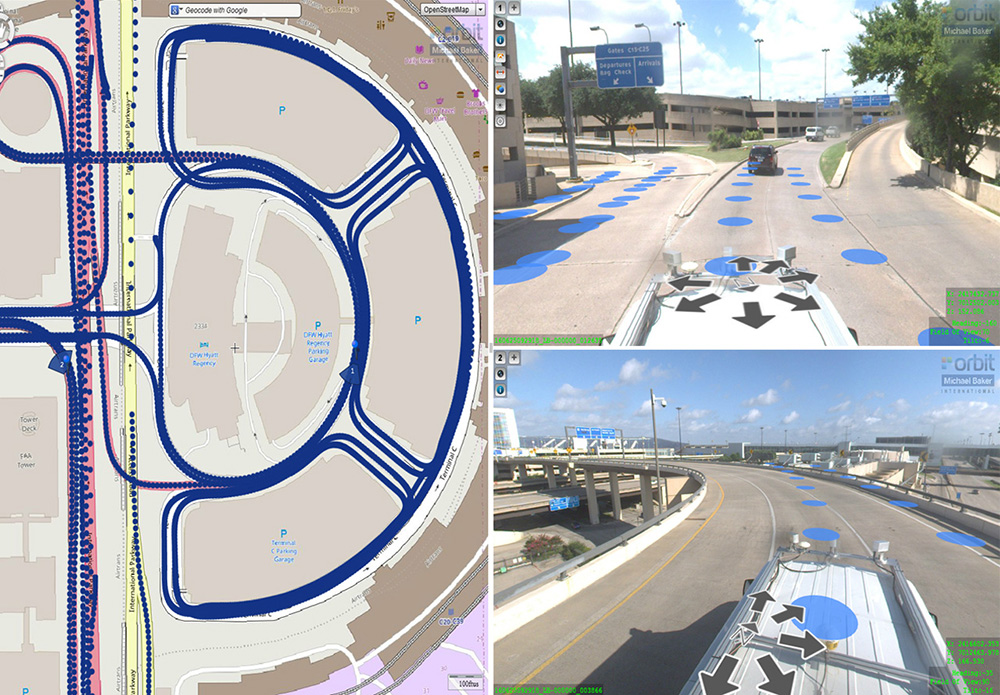

Our team completed a condition assessment of the Central Terminal Area roadway network on five terminals and 120 lane miles of roadway, using mobile LiDAR, a mapping solution that incorporates advanced mobile laser scanning sensors, cameras, and position and navigation to collect survey-quality data quickly and accurately; Laser Crack Measurement Systems (LCMS), a single-pass, 3D sensor for pavement inspections that uses laser-line projectors, high-speed cameras and advanced optics; and performed pavement visual inspections of two 13,401-foot long runways.

A second contract extension expanded the scope of the project to include the majority of the taxiways, high-speed exits and hold pads. This extension also included a subsurface condition investigation on runway 17C/35C, utilizing ground penetrating radar (GPR), a nondestructive imaging method that uses radar pulses to image below the pavement surface and soil-testing of the runway subgrade.

Our innovative one-vehicle solution collected data along all roadways comprising DFW’s landside area, and 95 percent of all airfield surfaces including: runways, taxiways, airfield roads and aprons. In total, they collected data on more than 1,300 linear miles on DFW grounds.

The LiDAR collection system included sensors that blanket a 235-meter-wide collection swath with up to 1.2 million laser shots per second – each to survey-grade accuracy. The system also includes four five-megapixel digital cameras and a 360° spherical camera for capture of high-resolution digital images suitable for attributing features and QA validations.

Using the newly acquired LiDAR, photography, traditional surveying, static scanning and legacy GIS data, our LiDAR technicians performed feature extraction and populated a GIS database with required features and attributes.

Innovation

“With more than three-million visitors each month and approximately 1,850 flights daily, there’s very little downtime to perform data collection around DFW’s terminals and runways. With our innovative LiDAR solution, we were able to collect data around-the-clock with multiple crews, minimizing impacts to airfield operations.”

Stephen C.

Project Manager