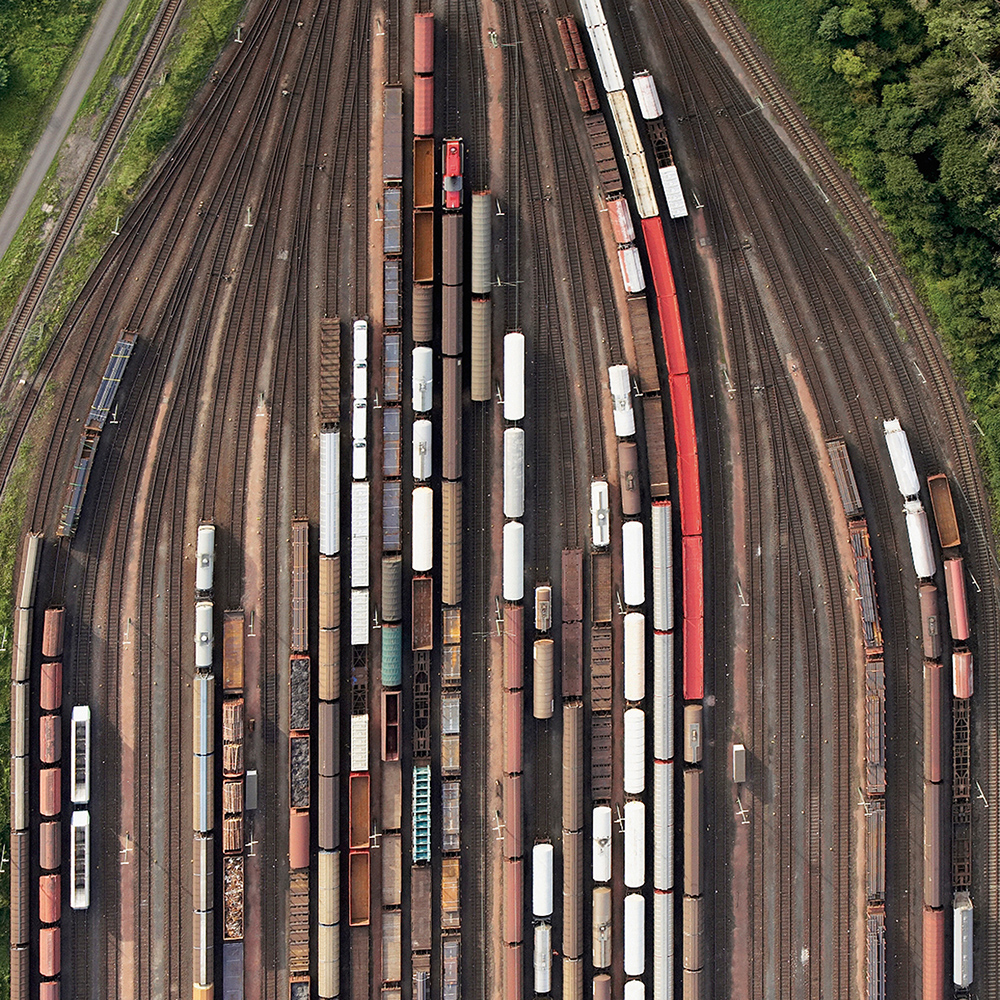

Moorman (Bellevue) Rail Yard

Bellevue, Ohio

Michael Baker provided engineering, design, surveying and permitting services for an expansion project to double the capacity of the Moorman (formerly Bellevue) Rail Yard to meet the rising demand for freight rail transportation. The rail yard encompasses approximately 620 acres in an unincorporated area in Huron and Erie Counties and is used for the classification and movement of freight.

As part of this multi-faceted project, our team helped Norfolk Southern expand the classification yard from 42 tracks to 80 tracks, plus a forwarding yard, receiving yard and mainline by-pass tracks, for a total of 37 miles of new track on the 620-acre site.

We provided surveying, geotechnical investigation, roadway and parking lot design, structure design, retaining wall design, utility identification and relocation coordination; environmental and construction permitting; and design of the air system, lighting and electrical power distribution and civil site design.

Two major structures were designed for efficient operations of the site. A 123-foot-long secondary access tunnel was designed and detailed to facilitate a 48-hour maximum track closure period. To achieve the short construction duration, the secondary access tunnel consisted of four-sided concrete precast boxes and precast concrete staircases.

The new hump bridge is a highly skewed 61-foot span steel girder bridge with composite concrete deck. Due to the proximity of the existing north hump lead track, the rear abutment was constructed using top-down construction methods and consisted of a secant pile wall with rock anchors drilled into bedrock. The forward abutment was constructed using conventional full height abutments on deep foundations. Due to the proximity of the lead track’s master retarder, a secant pile wall was designed for this wingwall and was braced off the forward abutment wingwall using steel struts.

The key challenge for this project was to provide “fast track” design and permitting. It was critical for our team to be proactive in developing the project schedule and to anticipate and resolve key choke points in advance, including all necessary permits. The design needed to be creative to minimize impacts to wetlands by realigning tracks to design for the increased capacity while maintaining the existing footprint of the yard to the extent possible. The structures were designed to accommodate adjacent rail operations and minimize track closures. The poor soil conditions necessitated a combination of structural elements to meet the deflection requirements.

Today, the Moorman Rail Yard is the largest rail yard on the Norfolk Southern system.

Innovation

“This was a complex project, especially from an environmental standpoint, and we had to become more creative in our design to minimize the footprint.”

Kirsten B.

Project Manager